WATER PUMPS

Why GMB WATER Pumps?

Not all water pumps are the same. Here’s what makes our water pumps stand out.

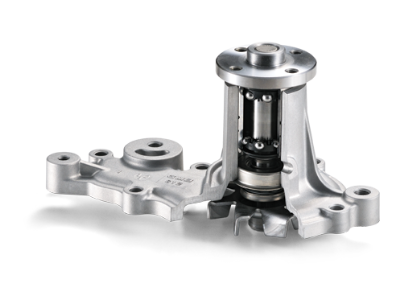

High-Strength Steel Bearing

GMB has manufactured bearings for over 75 years in the global market for both the OEM and aftermarket industries. GMB has studied all aspects of bearing manufacturing to design the highest-quality bearings with proper high-grade steel, precision bearing race machining and polishing, and proper grease selection. GMB uses roller bearings for all high-load applications.

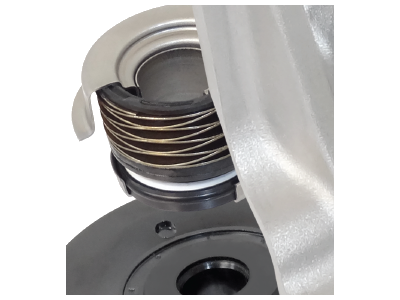

Proprietary Formulated Mechanical Seal

GMB Mechanical Shaft Seals are made with proprietary elastomers and agents for protection and sealing power. GMB Shaft Seals utilize carbon and ceramic sealing surfaces for superior wear resistance.

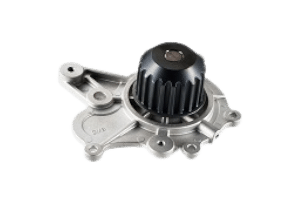

Precision OEM-Spec Water Pump Housing

GMB Water Pump Housings are manufactured to match the exact OEM-spec materials (cast iron, aluminum, or stamped steel). Each housing is precision measured using state-of-the-art technology to be dimensionally correct up to a 99% accuracy with strict tolerance limits.

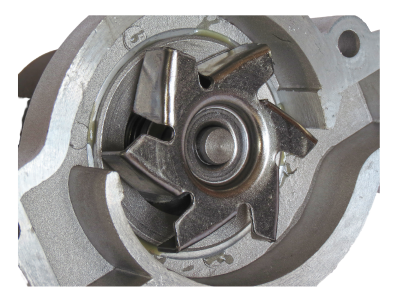

Precision-Formed Impeller

GMB Water Pump Impellers are manufactured to match the exact OEM-spec materials (metal or polymer composite) based specifically on the OEM design. Each impeller is also precision measured to be dimensionally correct up to a 99% accuracy with strict tolerance limits.

We're Continiously Developing New Products

We research, manufacture, and release hundreds of new products every year to make sure we have the parts you need.

Latest Water Pump News

How To Maximize The Performance And Lifespan Of Your Water Pump

Preventative maintenance is the key to maximizing the performance and durability of any water pump. Here’s a list of maintenance tips to share with your customers:

- Check coolant fluid levels with every oil change. Coolant should be changed approximately every 30,000 miles.

- Always use the vehicle manufacturer’s recommended coolant. Avoid off-brand coolants as they tend to have a lower level of ethylene glycol concentration and higher levels of acidity/alkalinity which drastically reduce the lifespan of a water pump.

- If not using a pre-mixed coolant, make sure to mix with distilled water rather than tap water. Tap water has small amounts of metals that can accelerate corrosion as it lacks lubricating, cleaning, and anti-rust properties, which can accelerate deterioration of the cooling system components.

- It’s recommended water pumps be replaced every 60,000 miles as a preventative maintenance item to ensure the engine’s cooling system is running adequately.

- When replacing the water pump, make sure to do a full coolant system flush to purge any residual contaminants and sediment deposits.