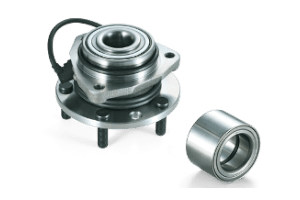

WHEEL BEARINGS AND HUB ASSEMBLIES

Why GMB WHEEL BEARINGS AND HUB ASSEMBLIES?

Not all wheel bearings and hub assemblies are the same. Here’s what makes ours stand out.

High Grade Steel Bearings

GMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.

Roll Formed High-Grade Steel Hub

GMB Wheel Bearing & Hub Assemblies contain specially formulated bearing grease. This special bearing grease has superior lubrication, enhanced thermal dissipation, water wash-out resistance, and better ability to lock in oils to keep the bearings rolling at optimal performance!

Specially Formulated Bearing Grease

GMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.

Triple & Quadruple Lip Sealing

GMB Hub Bearing Assemblies use a triple and quadruple lip sealing technology. This technique uses high temperature resistant rubber to achieve maximum bearing protection against dust, water and road debris.

OEM Spec ABS Sensors

ABS sensors used with GMB Wheel Hub Assemblies are manufactured with premium wire casings with 99.90% pure copper on the internal wiring for greater electrical conductivity and optimal performance. Our sensors are rigorously tested using the latest state-of-the-art equipment to ensure that the signal waves meet or exceed OE specs, and Electromagnetic Radiation Detectors to detect noise to eliminate radio interference.

We're Continiously Developing New Products

We research, manufacture, and release hundreds of new products every year to make sure we have the parts you need.

Latest Hub Assembly & Wheel Bearing News

How To Maximize The Performance And Lifespan Of Your Hub Assembly

Preventative maintenance is the key to maximizing the performance and durability of any hub bearing. Here’s a list of maintenance tips to share with your customers:

- When replacing your Wheel Bearing & Hub Assembly inspect and clean mounting point surface to ensure a level installation

- Inspect lug nuts for inner thread stripping and rust

- Make sure ABS cable is secure and clear of moving parts

- Replace suspension parts when needed to prevent unnecessary wear and tear on your bearings

- Rotate your tires every other oil change to maintain an even tire wear pattern for a smooth ride

- Tighten bolt to the correct torque specification as outlined by the OEM manufacture specific for your vehicle

- Check your wheel lugs for proper torque every tire rotation

- Check for proper wheel alignment at least once per year

- AVOID POTHOLES