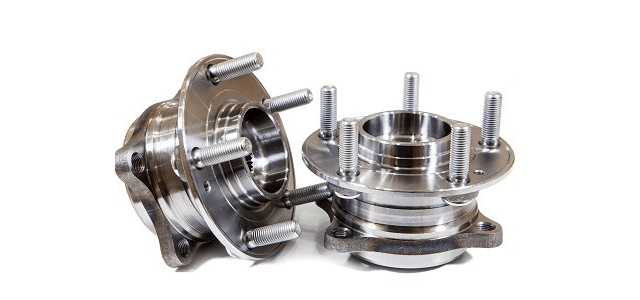

New Wheel Hub Bearing Assemblies Can Be Stiff and Hard To Turn – Here’s Why

Did you notice some stiffness when installing a new wheel hub bearing assembly? If so, you may worry that there’s something wrong with the new assembly. Most likely you have nothing to worry about. Yet, you still need to make sure that nothing went wrong during the installation process.

Is it normal for a new wheel hub bearing assembly to be stiff and hard to turn? Yes and no. In some cases, it’s normal. In other cases, it’s not.

When It’s Normal

It can be normal for some wheel bearings to be stiff and hard to turn right after installation. That’s because some manufacturers pre-fill the hub units and sealed bearings with high quality bearing grease. They use automated machinery to inject the grease, because they know that greasing bearings by hand is a chore, and that it won’t always be done well.

Manufacturers make sure to pre-fill these units with grease that is:

- High load

- High temperature

- High viscosity

In other words, expensive, mineral oil-based grease with different additives. It’s important for the grease to have high viscosity. Your wheel bearing is a bit stiff after installation because the grease hasn’t worn in enough. A few miles after installation, and it will be OK. Certain elements in the pre-filled grease will break down and allow the bearing to turn normally.

When It’s Not Normal

If you use an OEM or a high end OE-quality wheel hub bearing assembly, you have nothing to worry about. If you use a refurbished or a cheap aftermarket assembly, the stiffness may be a problem.

We strongly caution against using refurbished wheel hub bearing assemblies. It’s quite tricky to refurbish one. You have to make sure that all the clearances are right. While you can reuse the drum, you should never reuse the bearing itself. It’s possible for a manufacturer to refurbish hub assemblies the wrong way. The chances of running into issues with a refurbished hub assembly is pretty high.

Are you using a refurbished (or a cheap aftermarket) wheel hub bearing assembly? Do you notice stiffness? If your answer to both questions is yes, chances are the hub bearing assembly is the problem. Sometimes the bearings inside are too thick to move. The best way to determine if the hub assembly is the issue is to listen for any strange noises like:

- Screeching noise

- Grinding noise

If you keep driving with a bad refurbished hub assembly, the bearing will wear out faster than it should. It’s better to play it safe and replace it with a high quality bearing assembly.

You Don’t Have To Worry About This Issue With A GMB Wheel Hub Bearing Assembly

This is a good example of why quality is very important when it comes to wheel hub bearing assemblies. You can’t go wrong with a GMB wheel hub bearing assembly. At GMB, we make OE-quality bearing assemblies with:

- OEM dimensions

- High grade steel

- Specially formulated bearing grease

- Triple and quadruple lip sealing

GMB wheel hub bearings rarely fail early. Some of the most common causes of wheel hub bearing failure include:

- Hitting potholes or sunken man hole covers at high speeds

- Hitting curbs or speed bumps at high speeds

- Poor quality assembly

Wheel bearings are always under constant pressure, even when the car is parked. So if you want a wheel hub bearing assembly to last as long as possible, get a high quality unit like GMB. Read more about GMB wheel hub bearing assemblies here.

How To Make Sure That The Wheel Hub Bearing Seats The Right Way During Installation

You want to make sure there is no debris or imperfections in the bearing bore or axle surfaces (that come in contact with the bearing). Any debris or imperfections in those areas can keep the bearing from seating properly.

So when you replace the wheel hub bearing assembly, take the time to check and clean the:

- Bearing bore

- Axle surfaces that come in contact with the bearing

You can use a snap bore gauge to check the bore for roundness. You want the gauge to rotate easily within the bore. If you find any debris or corrosion, clean it out. If you install the new bearing in an imperfect bore, it won’t seat the right way. This will result in stiffness and eventual bearing failure.

MORE CONTENT

Stay current!

Sign up here to get the latest news

and updates on all things GMB.

Sign Up To Receive GMB News & Updates!