3 Reasons Fleets Should Encourage U-Joint Replacement

For fleet managers, one of the keys to success is cost efficiency. Cost efficiency is a pretty simple concept. It simply means that your fleet performs reliably with the lowest possible overall maintenance and repair costs. Preventive maintenance is key to achieving cost efficiency.

Every fleet manager is familiar with the idea of routine fluid and filter changes being done to prevent more expensive problems down the road. But not everyone knows that u-joints should be part of a fleet’s preventive maintenance schedule. Techs should be trained that it’s always OK to replace a u-joint as soon as it begins to fail. And drivers should be taught to immediately report any symptoms of bad u-joints. Here are three reasons why:

1. Bad U-Joints Can Lead To Very Expensive Problems

Ignoring a failing u-joint can lead to more expensive problems down the road. Let’s talk about some of the most common things that happen when u-joints begin to fail:

1. Leaking Transmission

The vibrations caused by a bad u-joint cause the driveshaft’s stub shaft to rotate out of round. This causes the transmission’s rear seal to fail. Fluid will leak out of the transmission. If the fluid gets low enough, the transmission will be damaged. The same thing can happen to a transfer case.

2. Leaking Differential

A bad u-joint at the rear of the driveshaft can ruin the pinion seal, in the same way the transmission seal can be ruined. Gear lube can leak out of the differential, potentially causing damage to the ring and pinion assembly.

3. Damaged Bearings

If they go on long enough, the vibrations from a bad u-joint can damage any of these bearings:

- The transmission output bearing (if there is no transfer case)

- The transfer case output bearing

- The pinion bearing

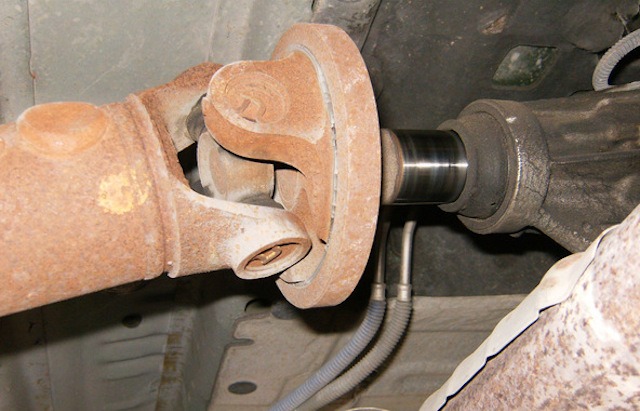

4. Broken Driveshaft

The u-joint connects the driveshaft to the transmission and rear differential. So when a u-joint begins to fail, the driveshaft can start vibrating or moving around. If the U-joint gets bad enough, the driveshaft can break free from the u-joint. The loose driveshaft will beat on everything it can reach while the truck coasts to a stop. The driveshaft will be damaged as well as other parts. At that point, your driver and load will be stranded on the side of the road. That means:

- Tow bills

- Emergency repair bills

- Late delivery penalties or refunds to customers

- A lot of lost productivity

So even if you have a hefty rainy day fund for towing, etc., driveshaft repair bills, lost productivity, and additional repairs may wipe it out.

5. Serious Collision

U-joints tend to fail completely during hard acceleration. A catastrophic failure on a highway on-ramp, for example, can be a big problem. When that happens, the vehicle won’t have power and might cause a serious collision with the car(s) behind you.

2. Bad U-Joints Are Easy To Diagnose

Drivers can often feel u-joints starting to loosen if they know what symptoms to look for. When that happens, your technicians should check the u-joints as soon as possible. Checking u-joints is a pretty quick and easy process. They only have to look for play in the u-joint. Here’s a great guide on inspecting u-joints.

If your drivers notice one or more of the following signs, chances are good that one of your trucks’ u-joints is on its last leg.

- Squeaking or clunking noise when shifting from forward to reverse or vice versa

- Vibrations felt through the whole vehicle while driving at high speeds

- Fluid leaking from the rear of the transmission or transfer case

- Fluid leaking from the front of the differential

It’s a good idea to educate your drivers on the symptoms of a bad u-joint. If your drivers can spot the symptoms:

- They’ll get to alert your techs right away

- Your techs can replace the u-joints before they completely fail and cause damage to other parts

3. Replacement U-Joints Are Inexpensive And Easy To Install

In this case, an ounce of prevention is worth 50 pounds of cure. U-joints are pretty inexpensive. Compare the cost of a replacement u-joint to the cost of repairs from u-joint failure (see above), and you’ll see that the former is much cheaper.

U-joints are easy to replace, too. So there’s no reason to put off a u-joint replacement.

Replacing U-Joints

It’s wise to stock up on replacement u-joints for your fleet. When one of your vehicles has u-joint failure, your techs can replace the u-joint(s) as soon as possible.

It’s also important to use high quality replacement u-joints. It will make a world of difference. For example, you’ll save a lot of time and money in replacement costs. High quality u-joints are much less likely to fail.

GMB is a leading brand for u-joints, and for a good reason. All GMB u-joints:

- Are built with high quality materials

- Contain heavy duty needle bearings

- Come with an exact fit snap ring

- Go through multi-stage testing for maximum quality control

MORE CONTENT

Stay current!

Sign up here to get the latest news

and updates on all things GMB.

Sign Up To Receive GMB News & Updates!