Critical Water Pump Components

Everyone who understands how modern engines work understands that water pumps are critical to your vehicle’s operation. Without a good water pump, your engine would be as hot as blacktop in Phoenix during the summer—and that’s not a good thing.

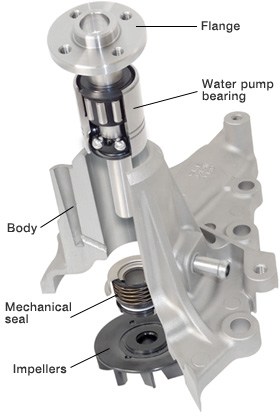

However, not many people understand the intricacies of water pumps. There are five key components in mechanical water pumps, all of which are critical to ensuring the pump’s performance and reliability.

At GMB, we take great pains to make sure our replacement water pumps meet or exceed OE specs, with exacting attention to each of the components listed below.

The Housing/Body

The pump housing is the outer shell that encases the pump. Typically, the housing is constructed of cast iron or aluminum, but there are also applications where the housing is made from stamped-steel. The housing is important to the function of the water pump because:

- The housing material must be sufficiently thick to sustain pressure applied from the drive belt as well as the internal pressure of the coolant system.

- The housing is exposed to considerable amounts of heat, so it must be properly designed and manufactured.

A mistake in the manufacturing process of a water pump housing can lead to premature bearing failures, fractures, or even catastrophic rupture.

The Impeller

The impeller is the part of the water pump that distributes coolant throughout the cooling system. The impeller must be properly designed to provide the correct system pressure. An incorrectly sized impeller will lead to insufficient coolant system flow rates and insufficient cooling. At GMB, all our impellers are designed to meet OEM specifications. The only exception is our high performance water pumps, which are sized to provide a specific flow rate at a specific RPM.

Though impeller failure is rare, it can happen when the impeller blades slip when the engine is started. Impeller corrosion can also occur from unsuitable or deteriorated coolant. The best ways to prevent this are to initiate regular coolant maintenance, always use the specific coolant for your application, and invest in quality parts such as those from GMB.

The Bearing

The bearing is the mechanical support that continually rotates the impeller. As stated above, the impeller must continually rotate in order to disperse coolant throughout the system. There are a variety of ways bearings can fail, including:

- The oxidation of lubricant on the bearing surface

- Over-tightening of drive belts

- Imperfect manufacturing processes

- Bad design

While all bearings will eventually wear out, a properly designed water pump bearing should last the life of a vehicle’s engine (or longer) assuming normal day-to-day use.

The Pump Pulley/Hub Flange

The pulley/hub flange attaches to the bearing shaft assembly, connecting the power source for impeller rotation. If the pulley breaks or malfunctions, the result will most likely be overheating as well as damage to related components.

The design of a water pump pulley is a common source of problems, at least when using water pumps that aren’t designed to OEM specifications. This is because small variations in the size/configuration of the pulley can lead to fitment, noise, or excess wear problems.

The Bearing Seal

The bearing seal is what protects the bearing assembly from coolant and other contaminants. If there’s one component that makes or breaks any given water pump, the bearing seal is that component.

Bearing seal designs will vary from one application to the next, but all bearing seals should:

- Function properly at the extreme edges of pump performance, meaning it will work just as well at redline under WOT as it does at idle during engine start

- Not distort or deteriorate as fluid pressure changes

- Prevent any debris or sediment in the cooling system from entering the pump

- Be part of a system that’s designed to work well together

That last point – that a good bearing seal is part of a system – is perhaps the most important. When water pumps are manufactured by one single company (especially a company with considerable experience building water pumps), the seals tend to mesh quite nicely with the bearing, bearing shaft, etc.

However, when seals are sourced from one company, bearings from another, shafts from someone else, etc. – and then the whole pump is assembled – the odds of getting a good “system” are reduced.

What Makes GMB Water Pumps Better Than The Rest?

A bad water pump can lead to a variety of problems, from a leaking cooling system to catastrophic engine failure. At GMB, we have decades of experience manufacturing water pumps. Many of our clients are automakers, well-known national parts chains, and even premium after-market brands that re-sell our products.

We’ve become one of the leaders in water pumps in the auto industry by focusing on each individual component. Our pump housings are made from materials best suited to the specific application. Our impellers are sized for each and every application – there are no “one size impeller fits all pumps” compromises. Our bearings and bearing seals are world class, as our company is a manufacturer of premium bearings known all over the world.

Finally, we take great care to match OEM specs for each and every water pump we make. That way, we know our customers (be they consumers installing a pump themselves, professional auto technicians, or automakers) will get the right fit every time.

Learn more about GMB water pumps.

MORE CONTENT

Stay current!

Sign up here to get the latest news

and updates on all things GMB.

Sign Up To Receive GMB News & Updates!