4 Tips To Make Sure a Timing Belt and Water Pump Replacement Goes Smoothly

No one enjoys doing the same job twice, but this is especially true of timing belt and water pump replacements. If a timing belt and water pump replacement isn’t done correctly, one of these parts will fail. That means you would have to go into the engine again and replace one of these parts (or both). Not only will a botched timing belt and water pump replacement reflect poorly on your shop, but they’ll also eat up a lot of your time because it’s a difficult and labor-intensive repair.

So it’s best to get a timing belt and water pump replacement job right the first time. To make sure this process goes smoothly, there are some things to remember:

1. Check & Replace the Belt Tensioner

The belt tensioner is an inexpensive part that’s easy to replace. When a belt tensioner fails, the timing belt snaps, leading to major problems. More specifically, the valves can get bent, the cylinder head or camshaft can get damaged, and/or the piston and cylinder walls can get damaged. That means hundreds or thousands of dollars in repairs.

So you should never hesitate to replace an old belt tensioner along with the timing belt and water pump.

2. Don’t Turn or Rotate the New Water Pump With Your Hands

To ensure the water pump rotates freely (and sucks coolant in properly), you have to manually rotate it. However, never do it with your hands because it can damage the seal inside the pump and cause premature pump failure. Instead, use a wrench.

3. Purchase the Parts From the Same Manufacturer

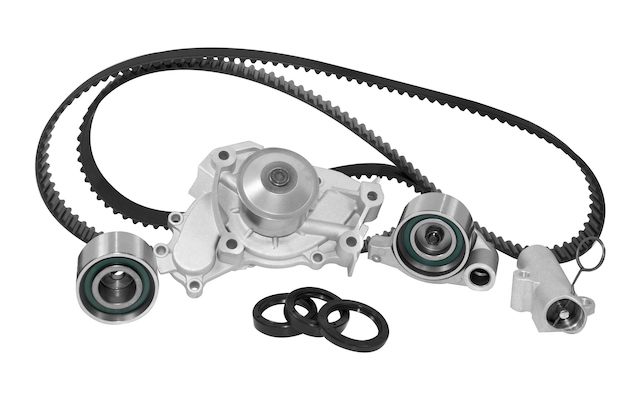

For easy replacement and smooth operation, purchase all of the parts you need in a kit from the same manufacturer. At GMB, we offer OE-quality timing belt kits with water pumps. All of our parts are built with premium OE-quality materials, and they go through rigorous quality control testing. Our timing belt kits with water pumps come with everything you need, including gaskets and seals.

4. Use the Right Coolant

It’s really important to use the right coolant while refilling the cooling system. It might sound obvious, but it’s fairly common for professional technicians to use the wrong coolant. The wrong coolant can destroy an engine. Mismatched coolants can coagulate and form a gel that inhibits cooling. In no time at all, an engine with gel for coolant will have major problems. Mainly, the cooling system will have trouble keeping the engine cool, meaning the engine will eventually overheat.

The wrong coolant will also fail to protect the mechanical seals in the water pump and allow particles to get into the pump. This article has more information on what may happen if you put the wrong coolant into the engine. We can’t stress enough how important it is to use the right coolant. If a customer experiences major engine problems as a result of the wrong coolant being put into their engine, your shop could be liable for all the damages.

Conclusion

Taking precautions and approaching timing belt and water pump repair with care will save you the hassle of having to redo a tedious, time-consuming job.

MORE CONTENT

Stay current!

Sign up here to get the latest news

and updates on all things GMB.

Sign Up To Receive GMB News & Updates!