How (And Why) To Measure Timing Belt Tension

Una correa de distribución es una correa de goma ubicada en la parte delantera del motor. Sincroniza la rotación del cigüeñal con la rotación del árbol de levas. Muchos motores modernos tienen un diseño de motor de interferencia. Esto significa que, si el movimiento de los pistones y el movimiento de las válvulas no están perfectamente sincronizados, interferirán (chocarán) entre sí. La correa de distribución evita la colisión al mantener la distribución de válvulas sincronizada con el cigüeñal y los pistones.

Para que la correa de distribución funcione correctamente, debes mantener la tensión adecuada.

Por qué es importante que una correa de distribución tenga la tensión correcta

El tensor de la correa de distribución es un componente instalado en la parte delantera del motor. La correa de distribución se desplaza sobre una pequeña polea que forma parte del tensor. El propósito del tensor es sujetar la correa de distribución en su lugar y mantener la tensión correcta en la correa de distribución. Lo hace mediante el uso de un resorte o fuerza hidráulica para empujar la polea hacia la correa de distribución para mantener la tensión correcta.

A veces, el tensor puede fallar o, a veces, la correa de distribución puede fallar. Surgirán ciertos problemas cuando la correa de distribución esté demasiado apretada o floja.

Qué sucede cuando la correa de distribución está demasiado ajustada

When the timing belt is too tight, several problems may occur:

- A constant whining or droning noise

- The belt may wear prematurely

- They belt may stretch, causing it to become loose

- The tensioner pulley bearings may wear prematurely

- The belt may break

Obviously, if the timing belt breaks in an interference engine, major damage will occur.

What Happens When The Timing Belt Is Too Loose

If the timing belt is too loose, your engine may not run as smoothly as it should. A loose timing belt allows the crankshaft and camshaft to be less than perfectly in sync with each other. The engine will still run, but not as smoothly.

If you suspect that the timing belt’s too loose, look for the following symptoms:

- Less power than normal

- Uneven response when opening or closing the throttle quickly

- The engine shaking inappropriately when starting from cold

- Rough idle

The risky part about a loose timing belt is that a sudden deceleration followed by sudden accelleration may cause the belt to snap. The timing belt will get slightly loose when first letting off the gas, and suddenly get tight when the throttle is opened.

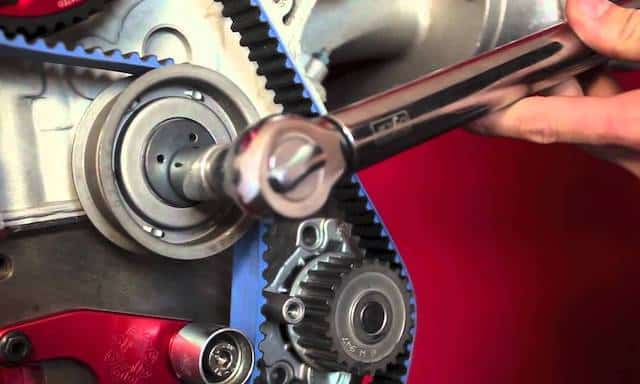

How To Measure Timing Belt Tension

There are two ways to measure timing belt tension:

- With a ruler

- With a timing belt tension gauge

The second method – with a timing belt tension gauge – is much more reliable.

Checking By Hand

If you don’t have a timing belt tension gauge on hand, you can check the tension with a ruler. Keep in mind that this method doesn’t always produce accurate results. To do this:

- Place a ruler next to the timing belt.

- Grab the timing belt with one hand and give it a tug.

If you can create more than 1/2″ of slack, then the timing belt needs to be tightened. If there is less than 1/4″ of slack, it’s too tight and needs to be loosened.

Checking With A Timing Belt Tension Gauge

A timing belt tension gauge is also called a timing belt tension meter. It’s a tool that measures the tension of a timing belt. There are several types of mechanical or digital tension gauges available. For whichever one you choose, be sure to follow the directions closely.

For some vehicles, you may be able to check the timing belt tension with a smartphone. When the belt is tight, if you pluck it like a guitar string, it will vibrate at a certain frequency. Some OEMs will provide the frequency specification for the timing belt. You can measure the frequency with an app on a smartphone. If the belt is too tight, the frequency will be higher than the spec. If the tension is too low, the frequency will be lower than the spec.

Check the tension of the timing belt occasionally, especially as the belt gets into the last half of it’s expected life. If the timing belt wears out too much, we recommend replacing it along with the water pump. Be sure to do it ASAP because a failed timing belt can cause irreparable engine damage. Even if the tension of the belt is ok, and the it doesn’t appear worn, it should still be replaced if the belt is past it’s recommended service interval.

MORE CONTENT

Stay current!

Sign up here to get the latest news

and updates on all things GMB.

Sign Up To Receive GMB News & Updates!