Avoid These 4 Mistakes When Installing A Fuel Pump

A surefire way to reduce comebacks is to install a part the right way the first time. It’s not easy to replace a fuel pump, but avoiding the most common mistakes will help the job go much more smoothly. Even the most experienced techs can make mistakes on a fuel pump replacement.

What Happens If A Fuel Pump Isn’t Installed The Right Way?

If a fuel pump isn’t installed correctly, it either won’t work at all or won’t supply enough fuel to the engine. When the fuel pump isn’t working right, your engine isn’t getting the amount of fuel it needs to run well. Your engine loses power and fuel efficiency.

The most common issues that crop up after a poorly done fuel pump installation are:

- Engine running rough

- Engine failing to start up

These are pretty serious problems and will upset even your most loyal customers. Do you want to reduce your shop’s chances of getting comebacks due to premature fuel pump failure? Make sure your techs avoid the 5 most common mistakes listed below.

1. Wiring The Fuel Pump The Wrong Way

In most fuel pump installations, the wiring is a plug and play. Simply plug the new fuel pump connector into the old vehicle side connector. This is difficult to screw up. However, sometimes the vehicle side connector is damaged, corroded or worn. There are two ways this can cause problems:

- Reusing an old connector can result in an intermittent or poor connection. An intermittent connection can cause stumbling when the connection is jarred. A poor connection can cause enough resistance to lower the amount of voltage reaching the pump. This causes the pump to turn more slowly than it should, and can shorten the life of the pump.

- Replacing the vehicle side connector should solve the issues with poor connections, but sometimes causes another problem. It’s really easy to mis-wire a new connector, when all the wires leading to it are dirty brown. Cleaning the wires, and taking a picture the connector before cutting it off is a good idea.

2. Not Replacing The Fuel Filter Too

Some older cars have a separate fuel filter. You need to always check for a fuel filter in every vehicle you work on. If there’s one, you need to replace it along with the fuel pump. A partially clogged fuel filter can kill the pump. A clogged fuel filter makes the pump work harder, shortening its life.

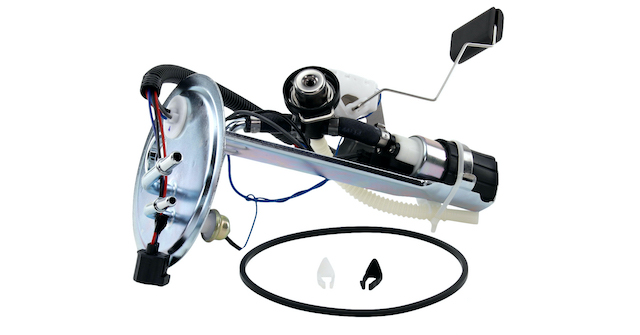

3. Using The Wrong Fuel Tank Gasket Size

When you drop the fuel tank, it’s always a good idea to put a new gasket on it when you install the fuel pump. Avoid using universal sized gaskets. You need to always make sure that you’re using the correct size. If you use the wrong sized gasket – whether it’s too big or too small – air will get into the fuel tank. This can trigger an emission systems code, and dropping the tank to put a new gasket in is an expensive fix. Quality replacement fuel pumps will include the correct gasket.

4. Allowing Debris To Enter The Fuel Tank When Removing It

It’s common for dirt and debris to build up on the outside of the fuel tank. When you remove a fuel tank, it’s easy for some of that debris to fall into the fuel tank and contaminate the fuel. When you have contaminated fuel, the strainer at the bottom of the fuel pump will clog up faster. This will lead to premature fuel pump failure. The good news is it’s very easy to prevent this. All you need to do is take the time to clean the debris off the fuel tank before dropping it.

MORE CONTENT

Stay current!

Sign up here to get the latest news

and updates on all things GMB.

Sign Up To Receive GMB News & Updates!